Imagine someday “prescribing” a full-sized, adult, 3D printed heart as easily as you might prescribe Amoxicillin. If it sounds like we’re cracking jokes about one of the body’s heartiest muscles, we’re not. And we’re absolutely not making light of the good people who desperately need a heart transplant. We are, however, feeling a bit giddy about a recent, first-of-its-kind advancement in regenerative medicine – the place where biology meets technology. It’s a breakthrough that’s pumping up a remarkable world of possibilities.

A FRESH Approach

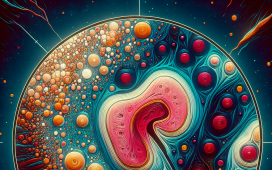

Let’s stroll back to August 2019, when Carnegie Mellon University (CMU) researchers published a paper in Science magazine that presented a unique technique to 3D bioprint tissue scaffolds made out of collagen – the major structural protein in the human body. The technique, dubbed Freeform Reversible Embedding of Suspended Hydrogel (FRESH), takes the field of tissue engineering one mighty step closer to 3D printing a healthy, adult human heart.1, 2

The FRESH 3D bioprinting method opens the door to fabricating collagen scaffolds capable of replicating the structure and function of tissues and organs, which was previously impossible using traditional biofabrication methods.

“What we’ve shown is that we can print pieces of the heart out of cells and collagen into parts that truly function, like a heart valve or a small beating ventricle,” says Adam Feinberg, PhD, professor of biomedical engineering and materials science and engineering, whose lab performed this

work. “By using MRI data of a human heart, we were able to accurately reproduce patient-specific anatomical structure and 3D bioprint collagen and human heart cells.”

The challenge to 3D print collagen, which makes up every single tissue in the body, turns out to be a sticky issue, explains Andrew Hudson, a BME PhD. student in Dr. Feinberg’s lab and co-first author on the paper, explains what makes it so hard to 3D print collagen. “(Collagen) starts out as a fluid – so if you try to print this in air it just forms a puddle on your build platform. So, we’ve developed a technique that prevents it from deforming.”

The FRESH 3D bioprinting method allows collagen to be deposited layer-by-layer within a support bath of gel, giving the collagen a chance to solidify in place before it’s removed from the support bath. With FRESH, the support gel can be easily melted away by heating the gel from room temperature to body temperature after the print is complete. This way, researchers can remove the support gel without damaging the printed structure made of collagen or cells.

GPS Set for Achievement

While thought leaders in regenerative medicine continue to put FRESH in the same sentence with an ability to 3D print a full-sized, adult human heart, Dr. Feinberg remains cautiously optimistic on this goal. He’s more of a step-by-step guy, working beside his team to fill reasonable and achievable “buckets” before leaping to thoughts of fully functional organ replication.

“FRESH may absolutely give us the ability to someday 3D print a human heart – but that’s a good decade away, maybe two. For now, step one is focusing on regenerative medicine,” Dr. Feinbergexplains. “In our lab, we’re using the FRESH technique to 3D print a collagen scaffold that we could implant in the human body to augment or improve the body’s own tissues’ ability to regenerate. So, bucket number one is learning how to recruit the body’s own cells to guide the regenerative process and repair tissue that would normally not have enough structure or the right growth factors to go it alone.”

At present, Dr. Feinberg’s team is developing a model to study volume metric muscle loss – and regenerative capabilities – in a large animal. “When we progress to studying human applications, this could affect so many people. Think about how we could help soldiers, victims in a car crash –anyone who loses a large piece of skeletal muscle that won’t regenerate on its own,” Dr. Feinberg says.

Guiding the body to repair damaged organ tissue or regions may even help reduce the growing need for new organs. “Often an organ doesn’t fail as a whole,” Dr. Feinberg stresses. “There may be a damaged region that slowly progresses until a new organ is needed. But until we understand how to create new, functioning organs – so we can replace damaged organs – patching could stall or even stop damage progression in many instances.”

Resources